Views: 0 Author: Site Editor Publish Time: 2025-12-27 Origin: Site

Have you ever wondered how rotary vane pumps work? These essential devices are crucial in various industries. Understanding their mechanics can significantly enhance efficiency and performance.

In this guide, we’ll explore the inner workings of vane pumps. You’ll learn about their components, applications, and maintenance tips. Get ready to dive deep into the fascinating world of rotary vane pumps!

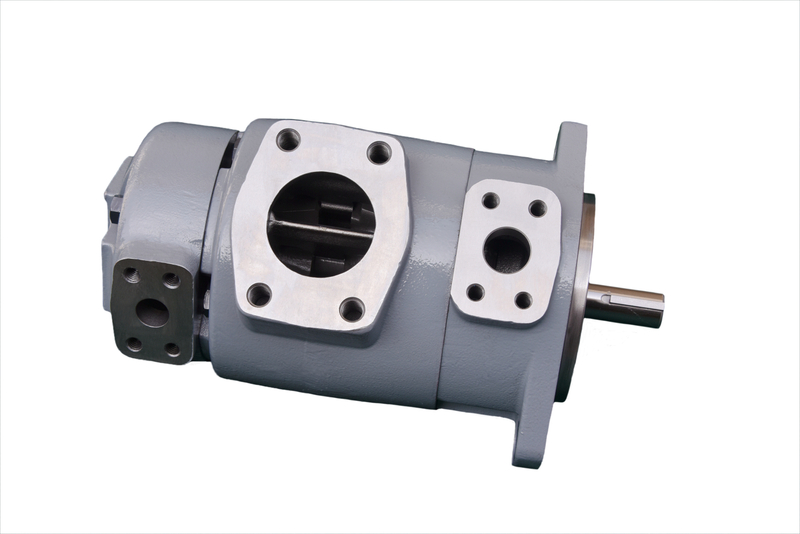

A vane pump is a type of positive displacement pump widely used in various applications. It operates by trapping a fixed volume of fluid and then moving it through the system. This mechanism ensures a consistent flow and pressure, making it essential for hydraulic systems, automotive applications, and industrial machinery.

The core functionality of a vane pump lies in its ability to create a vacuum that draws fluid in and compresses it for discharge. This process relies on the movement of vanes within a rotating rotor. As the rotor turns, it creates variable-volume chambers that facilitate fluid movement. This design not only enhances efficiency but also minimizes pulsation in the flow, which is crucial in many applications.

Understanding the components of a vane pump helps clarify how it operates. Here are the key parts:

The rotor is the heart of the vane pump. It is mounted on a drive shaft and features radial slots that hold the vanes. The rotor's eccentric design is critical; it allows the vanes to slide in and out as it rotates. This movement generates the necessary pressure to push the fluid through the pump.

● Function: Creates variable-volume chambers.

● Importance: Directly influences the pump's efficiency and performance.

Vanes are flat blades that slide in and out of the rotor slots. They play a vital role in the pumping action by sealing against the stator wall. Different types of vanes can be used, each designed for specific applications.

Type | Description | Applications |

Standard Vanes | Basic design for general use | Industrial machinery |

Low-Noise Vanes | Designed for quiet operation | Noise-sensitive environments |

High-Pressure Vanes | Optimized for high-pressure applications | Hydraulic systems |

The choice of vanes affects the pump's efficiency, noise levels, and ability to handle different fluid viscosities.

The stator, or cylindrical housing, encases the rotor and vanes. It provides structural support and maintains the pump's overall efficiency. The stator's design is crucial as it defines the shape of the chambers created by the rotor and vanes.

● Importance: Ensures proper alignment and sealing.

● Functionality: Prevents fluid leakage and maintains pressure.

Fluid enters and exits the vane pump through inlet and outlet ports. These ports are strategically placed to facilitate smooth fluid flow. The inlet port allows the fluid to enter the pump during the suction phase, while the outlet port is where the pressurized fluid is discharged.

● Inlet Port: Draws fluid into the pump, creating a vacuum.

● Outlet Port: Releases the pressurized fluid into the system.

In summary, each component of a vane pump plays a pivotal role in its operation. Understanding these parts helps users appreciate how vane pumps function effectively in various applications.

Understanding how a vane pump operates is essential for grasping its functionality. The mechanics of these pumps rely heavily on two key concepts: eccentric rotation and vane movement.

Eccentric rotation is fundamental to the operation of rotary vane pumps. The rotor is mounted off-center within the stator, creating a crescent-shaped cavity. This design allows the rotor to create variable-volume chambers as it spins. As the rotor turns, the distance between the rotor and the stator changes, which leads to the expansion and contraction of these chambers.

● Key Point: This eccentricity is what enables the pump to trap fluid effectively.

● Result: The vacuum created during rotation draws fluid into the pump, ensuring a continuous flow.

The movement of the vanes is crucial in determining how effectively the pump operates. When the rotor spins, centrifugal force pushes the vanes outward against the stator wall. This keeps the vanes in constant contact, forming tight seals that prevent leakage.

● Centrifugal Force: As the rotor accelerates, the vanes respond by sliding outward, which enhances fluid sealing.

● Pressure Generation: The combination of vane movement and the rotor's eccentricity creates pressure to push the fluid through the system.

The pumping cycle of a vane pump consists of four distinct phases: oil suction, sealing and transition, oil discharge, and continuous circulation. Each phase plays a vital role in ensuring efficient operation.

During the suction phase, the rotor's rotation creates a vacuum in the variable-volume chamber. As the chamber expands, it draws fluid from the inlet port.

● Process: The vanes move outward, increasing the chamber volume and decreasing pressure.

● Result: This creates a low-pressure area, allowing fluid to flow into the pump.

Once the chamber is filled with fluid, it transitions from the suction zone to the discharge zone. This phase is critical for maintaining a sealed chamber.

● Importance: Proper sealing prevents backflow and ensures that the fluid remains under pressure.

● Mechanism: The vanes continue to maintain contact with the stator, which keeps the chamber sealed during the transition.

As the rotor continues to turn, the chamber enters the discharge phase. The eccentric design causes the chamber volume to decrease, compressing the fluid inside.

● Pressure Generation: The reduction in volume increases the fluid pressure until it exceeds the system's pressure.

● Fluid Expulsion: The high-pressure fluid is then forced out through the outlet port, delivering power to the hydraulic system.

The final phase of the pumping cycle is continuous circulation. As the rotor keeps spinning, the process repeats itself, allowing for a steady flow of fluid.

● Cycle Repetition: Each chamber goes through the same four stages, ensuring consistent fluid delivery.

● Efficiency: This continuous operation minimizes pulsation in the flow, which is essential for many applications.

The mechanics of rotary vane pumps highlight their efficiency and reliability in various industrial applications. Understanding these principles can help users select the right pump for their specific needs.

When it comes to vane pumps, various designs cater to different applications. Understanding these types can help you choose the right pump for your needs. Here, we’ll explore three primary variants: single vane pumps, double vane pumps, and specialty vane pumps.

Single vane pumps are the simplest type of vane pump. They consist of a single rotor with vanes that slide in and out of slots. This design allows for effective fluid movement while maintaining a compact size.

● Characteristics:

○ Typically lightweight and easy to install.

○ Ideal for low to medium flow rates.

○ Suitable for applications requiring moderate pressure.

Applications:

Single vane pumps are commonly found in automotive systems, such as power steering, and in light industrial applications. They excel in situations where space is limited and efficiency is key.

Double vane pumps feature two rotors, each equipped with vanes. This design enhances the pump's performance, allowing it to handle higher flow rates and pressures.

● Advantages:

○ Increased efficiency due to reduced pulsation.

○ Better suited for high-pressure applications.

○ Enhanced durability and longer service life.

Feature | Single Vane Pump | Double Vane Pump |

Flow Rate | Moderate | High |

Pressure Capability | Low to Medium | Medium to High |

Efficiency | Standard | High |

Use Cases:

These pumps are often used in hydraulic systems, oil transfer, and industrial applications where consistent pressure and flow are crucial.

Specialty vane pumps are designed for specific applications, addressing unique requirements. They include low-noise designs and high-pressure models, among others.

● Overview of Unique Designs:

○ Low-Noise Vane Pumps: Engineered to minimize operational noise, making them ideal for residential or noise-sensitive environments.

○ High-Pressure Vane Pumps: Built to handle extreme pressures, suitable for industrial applications requiring robust performance.

Key Features:

● Customizable options for specific fluids or conditions.

● Enhanced materials for better resistance to wear and tear.

● Often incorporate advanced technology for improved efficiency.

Specialty vane pumps are essential in industries like food processing, pharmaceuticals, and any application where fluid characteristics vary significantly.

Each type of vane pump has its strengths, making it crucial to understand their features and applications. By selecting the right variant, you can ensure optimal performance in your specific use case.

Vane pumps are versatile devices used across various industries due to their efficiency and reliability. Their unique design makes them suitable for a wide range of applications, from automotive systems to food processing. Let’s explore some key industries that utilize vane pumps.

In the automotive sector, vane pumps play a crucial role in power steering and braking systems. These pumps provide the necessary hydraulic pressure to assist with steering and ensure effective braking.

● Power Steering: Vane pumps help create the hydraulic pressure needed to make steering easier. This enhances driver control and comfort.

● Braking Systems: They are also used in hydraulic brake systems, where consistent pressure is vital for safety and responsiveness.

Application | Functionality |

Power Steering | Assists in steering by providing hydraulic pressure |

Braking Systems | Maintains pressure for effective braking |

The food and beverage industry relies on vane pumps for various processes, especially in espresso machines and fluid transfer applications. These pumps ensure precise control over the flow of liquids.

● Espresso Machines: Vane pumps are used to generate the pressure needed to brew coffee, ensuring a rich flavor and optimal extraction.

● Fluid Transfer: They facilitate the movement of liquids, such as syrups and juices, while maintaining hygiene standards.

Key Benefits:

● Ensures consistent quality in beverages.

● Helps maintain the integrity of sensitive ingredients.

In industrial and laboratory settings, vane pumps are essential for vacuum generation and fluid transfer. Their ability to handle different fluids makes them invaluable in these environments.

● Vacuum Generation: Vane pumps create vacuums for various applications, including material handling and packaging.

● Fluid Transfer: They are used to move chemicals and other fluids safely, ensuring precise control over flow rates.

Application | Role |

Vacuum Generation | Creates vacuums for packaging and material handling |

Fluid Transfer | Moves chemicals with precision |

Vane pumps are also utilized in water treatment processes, particularly in reverse osmosis systems. They help maintain the pressure required for effective filtration.

● Reverse Osmosis: These pumps ensure that water passes through membranes efficiently, removing impurities and contaminants.

● Consistent Flow: They provide a steady flow of water, which is critical for maintaining system performance.

Advantages in Water Treatment:

● Enhances the efficiency of filtration systems.

● Supports sustainable water management practices.

Vane pumps are integral to many industries, providing reliable solutions for fluid movement and pressure generation. Their diverse applications highlight their importance in both everyday and specialized processes.

Vane pumps are widely used in various industries due to their unique characteristics. Understanding their advantages and disadvantages helps in making informed decisions about their applications. Let’s dive into the benefits and limitations of vane pumps.

One of the standout features of vane pumps is their self-priming ability. This means they can draw fluid into the pump without needing additional assistance, making them ideal for applications where the fluid source may be lower than the pump itself.

● Significance: Self-priming reduces setup time and increases operational efficiency. It allows the pump to start working immediately after being turned on, which is a significant advantage in many applications.

Vane pumps provide a stable flow rate, which is crucial for applications requiring consistent pressure. The design minimizes pulsation, ensuring smooth and reliable fluid delivery.

● Importance: Low-pulsation flow is essential in sensitive processes, such as chemical dosing and hydraulic systems, where fluctuations can lead to inaccuracies or equipment damage.

Feature | Advantage |

Self-Priming | Reduces setup time and enhances efficiency |

Stable Flow Rate | Ensures consistent pressure and smooth operation |

Another benefit of vane pumps is their compact design, which saves space in installations. Additionally, they operate quietly, making them suitable for environments where noise reduction is a priority.

● Space Efficiency: Their smaller footprint allows for easier integration into existing systems, especially in confined spaces.

● Noise Reduction: Quiet operation is particularly beneficial in residential areas or workplaces where noise levels must be kept to a minimum.

As industries evolve, so do the technologies that support them. Vane pumps are no exception, and several trends are shaping their future. Innovations in design and materials, along with market demands, are driving significant changes. Let’s explore these emerging trends.

One of the most exciting developments in vane pump technology is the focus on improving efficiency. Manufacturers are leveraging advanced engineering techniques and computational fluid dynamics to optimize pump designs.

● Emerging Technologies: New rotor configurations and vane profiles enhance fluid dynamics, reducing energy consumption while increasing flow rates. These advancements lead to more efficient pumps that can operate under a wider range of conditions.

● Performance Metrics: The goal is to achieve higher performance metrics, such as increased pressure capabilities and reduced operational costs.

Feature | Traditional Design | Innovative Design |

Energy Consumption | Higher | Lower |

Flow Rate | Moderate | Enhanced |

Operational Range | Limited | Expanded |

Sustainability is becoming a critical factor in manufacturing, and vane pump technology is adapting accordingly. The development of eco-friendly materials and designs is on the rise.

● Sustainable Materials: Manufacturers are exploring biodegradable and recyclable materials for pump components. This shift not only reduces environmental impact but also appeals to eco-conscious consumers.

● Green Design Principles: Innovations focus on minimizing waste during production and improving the overall lifespan of pumps, contributing to a more sustainable future.

The demand for vane pumps is increasing across various sectors, reflecting their versatility and reliability. Industries such as automotive, food and beverage, and water treatment are expanding their use of these pumps.

● Market Growth Insights: According to recent reports, the global vane pump market is projected to grow significantly over the next few years. This growth is driven by the need for efficient fluid handling solutions in diverse applications.

● Potential Future Applications: Emerging technologies, such as electric vehicles and advanced manufacturing processes, present new opportunities for vane pump integration. As these industries evolve, the demand for specialized vane pumps will likely increase.

Industry | Applications | Growth Potential |

Automotive | Power steering, braking systems | High |

Food and Beverage | Fluid transfer, espresso machines | Moderate |

Water Treatment | Reverse osmosis, filtration systems | High |

The future of vane pump technology looks promising, with innovations in design and materials paving the way for enhanced performance and sustainability. As market demands evolve, we can expect to see even more diverse applications for these essential devices.

Understanding rotary vane pump mechanics is crucial for effective fluid handling. These pumps offer various benefits, including efficiency and versatility. When selecting a vane pump, consider your specific application needs. This ensures optimal performance and reliability. For more detailed insights, further reading or consultation with experts is highly encouraged.