Views: 0 Author: Site Editor Publish Time: 2025-12-28 Origin: Site

Have you ever wondered how fluid moves smoothly in machines? Rotary vane pumps play a crucial role in this process.

These pumps use a unique mechanism to transfer liquids and gases efficiently.

In this article, we’ll explore what a vane pump is, how it works, and its importance across various industries.

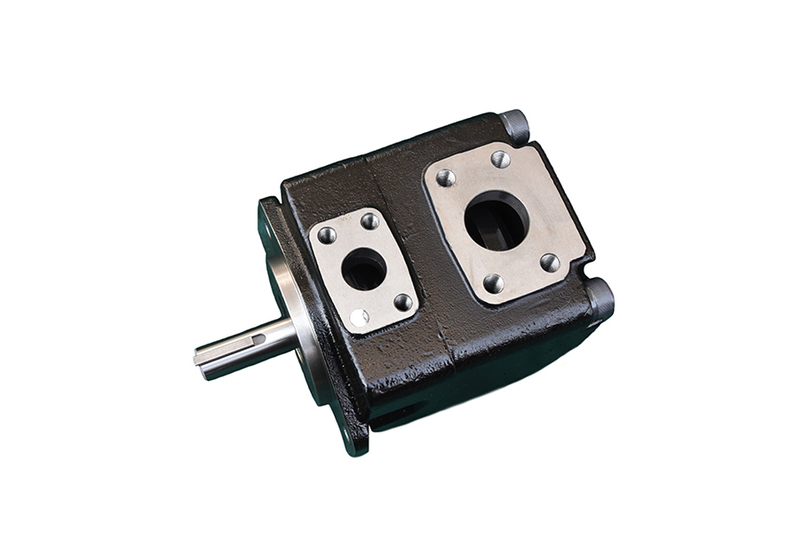

Rotary vane pumps are fascinating devices that utilize a positive displacement mechanism. This means they move fluid by trapping a fixed amount of it and forcing it into the discharge pipe. The heart of this operation lies in the rotor and vanes.

● Positive Displacement Mechanism: As the rotor spins, the vanes slide in and out of their slots. This action creates varying chamber sizes, allowing the pump to draw fluid in on one side while pushing it out on the other.

● Role of Vanes and Rotor: The vanes maintain contact with the pump casing, ensuring efficient fluid transfer. This design minimizes flow pulsation and contributes to quieter operation, making it ideal for various applications.

Vane pumps offer several advantages that make them a popular choice in many industries.

1. Low Noise Operation: Due to their design, these pumps operate quietly, which is essential in environments where noise reduction is crucial, such as in residential areas or laboratories.

2. High Efficiency and Durability: Vane pumps are known for their efficiency. They can handle a wide range of fluid viscosities while maintaining high performance. Their robust construction ensures a long service life, reducing the need for frequent replacements.

3. Self-Priming Capabilities: One of the standout features of vane pumps is their ability to self-prime. This means they can draw fluid into the pump without needing manual intervention, making them user-friendly and efficient.

When considering pump options, it's helpful to compare vane pumps with other types, such as gear pumps and diaphragm pumps.

Feature | Vane Pumps | Gear Pumps | Diaphragm Pumps |

Noise Level | Low | Moderate | Moderate to High |

Efficiency | High | High | Variable |

Self-Priming | Yes | No | Yes |

Fluid Types | Liquids and gases | Viscous liquids | Liquids, slurries |

Maintenance | Easy | Moderate | Moderate |

In summary, rotary vane pumps stand out due to their unique features and benefits. They excel in many applications, from automotive systems to food processing, making them a versatile choice in the pumping world.

Rotary vane pumps are crucial in the automotive industry, providing essential functions that enhance vehicle performance and safety.

● Power Steering Systems: These pumps pressurize hydraulic fluid, making steering easier and more responsive. This feature is vital for driver comfort and vehicle handling.

● Brake Boosters: Vane pumps generate the necessary vacuum to assist braking systems, improving stopping power and ensuring safety on the road.

● Transmission Systems: In automatic vehicles, these pumps maintain fluid pressure, facilitating smooth gear shifts. This contributes to a more enjoyable driving experience.

● Air Conditioning Systems: Vane pumps circulate refrigerant, ensuring efficient cooling and comfort for passengers, especially during hot weather.

Keister, a leading brand in automotive applications, employs rotary vane pumps for their reliability and efficiency in various systems, showcasing their importance in modern vehicles.

In the food and beverage industry, rotary vane pumps are indispensable for maintaining quality and consistency in product handling.

● Applications in Espresso Machines: These pumps create the pressure needed to brew espresso, delivering rich flavors and aromas. Consistency is key in coffee production, and vane pumps help achieve that.

● Use in Fountain Soda Dispensers: Vane pumps efficiently move syrup and carbonated water, ensuring a perfect mix for refreshing beverages. This is vital for customer satisfaction in restaurants and cafes.

● Role in Food Packaging and Vacuum Sealing: By creating a vacuum, these pumps help preserve food freshness and extend shelf life, which is crucial in packaging processes.

Keister is known for its precision vane pumps in the food processing sector, ensuring high standards in hygiene and efficiency.

Rotary vane pumps are widely utilized in industrial and laboratory settings due to their versatility and reliability.

● Vacuum Systems and Roughing Pumps: These pumps create vacuums for various applications, including material handling and packaging, enhancing productivity in industrial processes.

● Applications in Laboratories: In labs, rotary vane pumps are used for distillation, filtration, and degassing, maintaining consistent vacuum levels for accurate results.

● Use in Semiconductor Manufacturing: In this high-tech industry, Keister's vane pumps create clean environments for delicate processes, ensuring the quality of semiconductor products.

Beyond automotive and food industries, rotary vane pumps find applications in various fields.

● Fuel and Chemical Transfer: They efficiently handle low-to-medium viscosity fluids, such as gasoline and solvents, ensuring safe transfer.

● Water Treatment Processes: Vane pumps are utilized to manage water flow in treatment facilities, helping to maintain clean water supplies.

● Material Handling in Automation: In automated systems, these pumps power "pick-and-place" machines, allowing for efficient movement of parts.

● Woodworking Applications: They assist in clamping workpieces securely on CNC routing tables using vacuum hold-down techniques.

Here’s a quick overview of the various applications of rotary vane pumps across different industries:

Industry | Application | Notable Brands |

Automotive | Power steering, brake boosters, transmission | Keister, Bosch, Aisin |

Food and Beverage Processing | Espresso machines, soda dispensers, vacuum sealing | Keister, Graco, Hibar Systems |

Industrial and Laboratory | Vacuum systems, distillation, semiconductor manufacturing | Keister, Leybold, Edwards |

Other Key Uses | Fuel transfer, water treatment, material handling | Keister |

Keister's rotary vane pumps are essential across many industries, demonstrating their versatility and importance in everyday applications.

Rotary vane pumps offer several core advantages that make them a popular choice in various industries. Their design and functionality provide significant benefits in fluid transfer and equipment efficiency.

● Efficiency in Fluid Transfer: Vane pumps excel at moving liquids and gases with minimal energy loss. Their positive displacement mechanism allows for consistent flow rates, making them ideal for applications requiring precise fluid handling. This efficiency translates to lower operational costs and reduced energy consumption.

● Versatility Across Different Applications: One of the standout features of vane pumps is their versatility. They can handle a wide range of fluids, including viscous liquids, chemicals, and even gases. This adaptability makes them suitable for diverse industries, from automotive to food processing.

● Ease of Maintenance and Repair: Vane pumps are designed for straightforward maintenance. Their simple construction allows for easy access to components, making repairs quick and cost-effective. This ease of maintenance minimizes downtime and helps keep operations running smoothly.

● Long Service Life and Reliability: These pumps are built to last, often providing years of reliable service. Their robust design and materials ensure they can withstand harsh operating conditions, reducing the frequency of replacements and saving money in the long run.

Rotary vane pumps significantly enhance operational efficiency in various applications. Their unique features contribute to smoother operations and improved performance.

● Low Noise Operation: One key benefit of vane pumps is their low noise levels. This characteristic is particularly important in environments where noise reduction is essential, such as hospitals and residential areas. A quieter operation contributes to a more pleasant working atmosphere.

● High-Pressure Resistance: Vane pumps can handle high pressures effectively, making them suitable for applications requiring significant force. This capability is crucial in hydraulic systems, where maintaining pressure is vital for performance.

Here’s a quick overview of the advantages of rotary vane pumps:

Advantage | Description |

Efficiency in Fluid Transfer | Minimal energy loss and consistent flow rates |

Versatility | Suitable for various fluids and applications |

Ease of Maintenance | Simple access for repairs, reducing downtime |

Long Service Life | Durable design ensures reliability over time |

Low Noise Operation | Quieter performance for improved working conditions |

High-Pressure Resistance | Effective in applications requiring significant force |

Rotary vane pumps are essential in optimizing processes and enhancing productivity across various sectors. Their unique advantages make them a preferred choice for many applications, ensuring reliable and efficient operations.

When choosing a pump, it's essential to understand how rotary vane pumps stack up against other types, such as gear pumps and diaphragm pumps. Each pump has its unique features, benefits, and ideal applications, making the right choice crucial for efficiency and performance.

Rotary vane pumps and gear pumps are both popular options for fluid transfer, but they operate differently.

● Operating Mechanism: Vane pumps use rotating vanes to create chambers that trap and move fluid, while gear pumps rely on interlocking gears to push fluid through. This fundamental difference affects their performance and suitability for various applications.

● Flow Characteristics: Vane pumps provide a smoother flow with less pulsation compared to gear pumps. This makes them ideal for applications requiring consistent flow rates, such as in hydraulic systems.

● Viscosity Handling: While gear pumps excel in handling viscous fluids, vane pumps can handle a broader range of fluid viscosities, including gases. This versatility gives vane pumps an edge in diverse industrial applications.

Diaphragm pumps are another common choice, particularly in applications requiring chemical handling. However, rotary vane pumps offer several advantages:

● Higher Flow Rates: Vane pumps typically achieve higher flow rates compared to diaphragm pumps. This makes them more efficient for applications where large volumes of fluid need to be moved quickly.

● Lower Maintenance Needs: Vane pumps generally require less maintenance than diaphragm pumps. Their simpler design means fewer parts that can wear out or break, leading to reduced downtime and lower operational costs.

● Quieter Operation: The design of rotary vane pumps allows for quieter operation than many diaphragm pumps. This feature is especially beneficial in environments where noise levels must be kept to a minimum.

Rotary vane pumps shine in specific scenarios due to their unique advantages. Here are some situations where they are the preferred choice:

● Automotive Applications: In vehicles, where space is limited and efficiency is key, vane pumps are often used for power steering and brake systems due to their compact design and reliability.

● Food and Beverage Processing: Their ability to handle various fluids, including those with particulates, makes them ideal for food and beverage applications. Vane pumps ensure consistent flow and maintain product quality.

● Industrial Processes: In manufacturing settings, where efficiency and reliability are paramount, rotary vane pumps are favored for their versatility and ability to handle different fluid types.

Here’s a quick comparison of rotary vane pumps with gear and diaphragm pumps:

Feature | Rotary Vane Pumps | Gear Pumps | Diaphragm Pumps |

Operating Mechanism | Rotating vanes | Interlocking gears | Flexible diaphragm |

Flow Characteristics | Smooth, low pulsation | Pulsating | Pulsating |

Viscosity Handling | Broad range | Best for viscous fluids | Limited viscosity range |

Maintenance Needs | Low | Moderate | Higher |

Flow Rate | High | Moderate | Lower |

Noise Level | Low | Moderate | High |

Rotary vane pumps offer distinct advantages that make them suitable for a wide range of applications, from automotive to industrial processes. Understanding these comparisons helps in selecting the right pump for specific needs.

Choosing the right rotary vane pump involves careful consideration of several key factors. Each application has unique requirements, and understanding these can help in making an informed decision.

● Application Requirements: One of the first things to consider is the specific requirements of your application. This includes both pressure and flow rate. For instance, if the application demands high pressure, ensure the vane pump you choose can handle it. Similarly, evaluate the required flow rate; the pump should provide a consistent output to meet operational needs.

● Fluid Characteristics: The nature of the fluid being pumped is another crucial factor. Different fluids have varying viscosities and temperatures, which can affect pump performance. For example, if you’re working with highly viscous fluids, you’ll need a pump designed to handle such conditions efficiently. Additionally, consider the temperature range of the fluid. Some pumps are better suited for extreme temperatures than others, so make sure to match the pump specifications to the fluid characteristics.

● Space Constraints and Installation Considerations: Lastly, think about the physical space where the pump will be installed. Space constraints can limit your options, so it's essential to choose a pump that fits comfortably within the designated area. Additionally, consider how the pump will be installed. Some models may require more complex installation processes than others, impacting overall efficiency and maintenance.

When selecting a rotary vane pump, several specifications are essential to ensure optimal performance. Understanding these can guide your purchasing decisions.

● Displacement Options: Different vane pumps offer various displacement options, which refer to the volume of fluid the pump can move per cycle. This is a critical specification, as it directly influences flow rates and overall efficiency. Make sure to select a pump with a displacement that meets your application's demands.

● Performance Ratings: Performance ratings are another vital aspect to examine. These ratings typically include maximum pressure, flow rate, and efficiency ratings. Understanding these metrics helps ensure that the pump will perform effectively under your specific operational conditions.

Here’s a quick overview of the key specifications to consider:

Specification | Description |

Displacement Options | Volume of fluid moved per cycle |

Maximum Pressure | Highest pressure the pump can handle |

Flow Rate | Rate at which fluid is pumped |

Efficiency Rating | How effectively the pump converts energy to flow |

Temperature Range | Compatible temperature limits for fluids |

By carefully evaluating these factors and specifications, you can select a rotary vane pump that best meets your operational needs. The right choice will enhance efficiency, reliability, and overall performance in your specific application.

Maintaining a rotary vane pump is crucial for ensuring its longevity and optimal performance. Regular upkeep helps prevent issues that could lead to costly downtime or repairs. Here are some essential maintenance tips to keep your vane pump running smoothly.

● Regular Maintenance Tips: Schedule routine inspections to check for wear and tear on the vanes and seals. Clean the pump regularly to remove any debris or contaminants that could affect performance. Additionally, ensure that the lubrication is adequate; proper lubrication reduces friction and prolongs the life of the pump. It’s also important to check fluid levels frequently and replace fluids as needed to maintain efficiency.

● Monitoring Performance: Keep an eye on the pump’s performance metrics, such as flow rate and pressure. Any significant deviations from normal operating conditions could indicate a problem. Implementing a monitoring system can help you catch issues early before they escalate.

Even with regular maintenance, issues can arise. Knowing how to troubleshoot these problems can save time and resources.

● Common Issues: Some common problems include reduced flow rates, unusual noises, and overheating. Each of these symptoms can indicate different underlying issues, such as worn vanes, blockages, or inadequate lubrication.

● Troubleshooting Steps: If you notice a drop in flow rate, check for clogs in the intake or discharge lines. For unusual noises, inspect the pump for loose components or signs of wear. If overheating occurs, ensure that the pump is properly lubricated and that the cooling system is functioning effectively.

Here’s a quick troubleshooting guide for common issues:

Issue | Possible Cause | Suggested Action |

Reduced Flow Rate | Clogs or worn vanes | Check intake/discharge lines; replace vanes if necessary |

Unusual Noises | Loose components or wear | Inspect pump parts; tighten or replace as needed |

Overheating | Inadequate lubrication or cooling | Check lubrication levels; ensure cooling system is working |

Recognizing the signs of a failing vane pump is vital for timely intervention. Addressing issues early can prevent complete pump failure and costly repairs.

● Common Symptoms: Look out for symptoms such as fluctuating pressure, excessive noise, or visible leaks. If the pump is struggling to maintain consistent pressure, it may indicate vanes or seals are worn out. Excessive noise can be a sign of internal damage, while leaks often point to seal failures.

● Addressing Symptoms: If you notice fluctuating pressure, inspect the vanes and seals for wear. For excessive noise, disassemble the pump to check for damaged components. If leaks are present, replace seals or gaskets as necessary. Regular monitoring and prompt action can significantly extend the life of your vane pump.

By following these maintenance and troubleshooting guidelines, you can ensure that your rotary vane pump operates efficiently and effectively, minimizing downtime and maximizing productivity.

Understanding rotary vane pumps is essential for many industries. Their versatility allows them to handle various fluids efficiently.

These pumps are crucial in applications like automotive, food processing, and industrial settings.

By considering rotary vane pumps, you can enhance operational efficiency and reliability in your specific applications.

A: The lifespan of a rotary vane pump typically ranges from 5 to 15 years, depending on usage and maintenance.

A: Yes, rotary vane pumps can efficiently handle both liquids and gases, making them versatile for various applications.

A: Industries such as automotive, food processing, pharmaceuticals, and manufacturing commonly use rotary vane pumps.

A: Limitations include sensitivity to fluid contamination and potential performance issues with highly viscous fluids.