Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

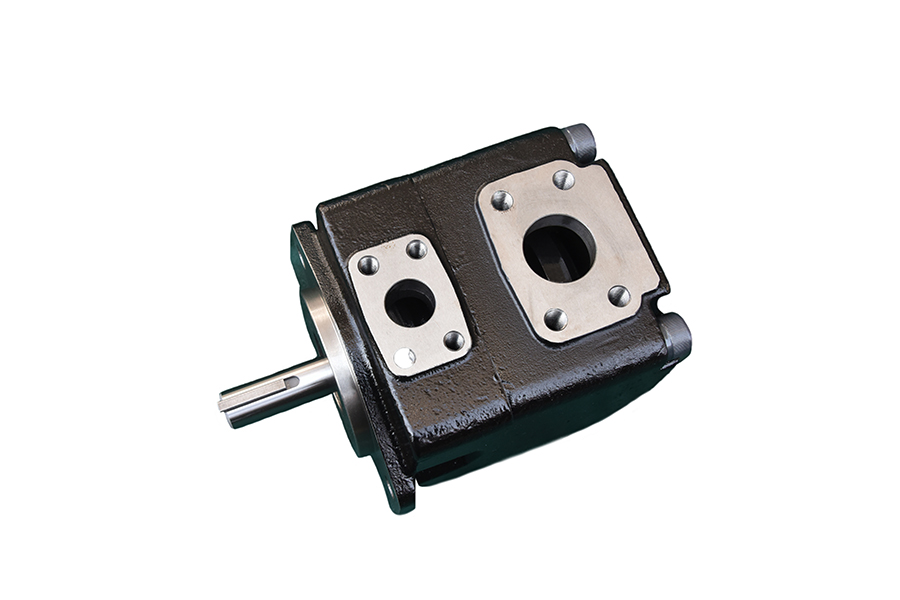

Are you looking for reliable hydraulic solutions? Vickers Vane Pumps are essential in various industries. These pumps enhance efficiency and performance in hydraulic systems.

In this article, we will explore the unique value of Vickers Vane Pumps. You’ll learn about their key features, benefits, and applications. Discover why they are a top choice for industrial needs.

Vickers Vane Pumps are a crucial component in hydraulic systems, providing reliable fluid power for various applications. These pumps operate based on a simple yet effective principle: rotating vanes within a cavity create a pressure differential, allowing fluid to flow smoothly. This design makes them suitable for a wide range of industries, from manufacturing to construction.

Understanding the components of Vickers Vane Pumps helps appreciate their functionality. The main parts include:

● Rotor and Vanes: The rotor is the heart of the pump, where the vanes slide in and out to create suction and pressure. This mechanism ensures a consistent flow of hydraulic fluid, making it efficient for demanding tasks.

● Cavity Design: The cavity is designed to allow the vanes to move freely while maintaining a tight seal. This design minimizes leakage and maximizes efficiency, ensuring optimal performance even under high pressure.

Component | Description |

Rotor | Central part that rotates to drive the vanes |

Vanes | Move in and out to create pressure and suction |

Cavity | Houses the rotor and vanes, facilitating fluid flow |

Vickers offers two main types of vane pumps: single-vane and double-vane designs.

● Single-Vane Designs: These pumps feature a straightforward mechanism that is easy to maintain. They are typically used in applications requiring lower flow rates and pressures. Their simplicity makes them a popular choice for smaller machinery.

● Double-Vane Designs: These are more complex and provide higher efficiency and flow rates. They are ideal for demanding applications, such as hydraulic systems in heavy machinery. The dual-vane setup allows for smoother operation and better performance under load.

Vickers is recognized as a top manufacturer of industrial hydraulic products. Their commitment to innovation and quality ensures that their vane pumps meet high standards. With decades of experience, Vickers has established itself as a trusted name in the hydraulic industry.

They focus on developing advanced technologies and maintaining rigorous quality control. This dedication to excellence enables Vickers Vane Pumps to perform reliably in various environments, making them a preferred choice for engineers and operators worldwide.

In summary, Vickers Vane Pumps combine innovative design and robust construction. Their unique components and types cater to diverse industrial needs, highlighting Vickers' role as a leader in hydraulic solutions.

Vickers Vane Pumps are celebrated for their innovative design and exceptional performance. They offer several key features that make them ideal for various applications, from industrial machinery to mobile equipment.

One of the standout characteristics of Vickers Vane Pumps is their low noise and vibration levels. This is largely due to their pressure-balanced 12-vane system, which minimizes pulsation and ensures smooth operation.

● Benefits for Indoor and Vehicle Applications: The quiet operation makes these pumps perfect for environments where noise reduction is crucial, such as in indoor industrial settings and vehicles. Operators can work comfortably without excessive noise interference.

● Comparison with Keister Vane Pumps: While both Vickers and Keister Vane Pumps prioritize low noise, Vickers' advanced design often results in superior performance in this area, making them a preferred choice for noise-sensitive applications.

Feature | Vickers Vane Pumps | Keister Vane Pumps |

Noise Level | Low | Moderate |

Vibration | Minimal | Noticeable |

Ideal Applications | Indoor, vehicles | General industrial |

Vickers Vane Pumps are known for their high power density, which allows them to deliver more power in a compact design. This efficiency is essential for applications that require reliable performance in limited spaces.

● Compact Design and Efficiency: Their compact design enables installations in tight spaces, making them suitable for various machinery. This efficiency translates into lower operational costs and reduced energy consumption.

● Examples of Applications: Industries such as construction, automotive, and manufacturing benefit significantly from this feature. For instance, in heavy machinery, Vickers Vane Pumps provide the necessary power without taking up excessive space.

Another significant advantage of Vickers Vane Pumps is their fluid versatility. They can handle a wide range of fluids, making them adaptable to different industrial needs.

● Capability to Handle Low-to-Medium Viscosity Fluids: These pumps excel at moving fluids with varying viscosities, ensuring smooth operation in diverse conditions. This adaptability is crucial in industries where fluid characteristics can change frequently.

● Tolerance for Dry-Run Conditions: Vickers Vane Pumps are designed to tolerate brief dry-run conditions. This feature minimizes the risk of damage and enhances reliability, especially in applications where fluid supply may be interrupted.

Ease of maintenance is a critical factor in the longevity and efficiency of hydraulic systems. Vickers Vane Pumps shine in this aspect due to their thoughtful design.

● Cartridge Design for Easy Maintenance: The cartridge design allows for quick and straightforward servicing. Operators can replace pump components without needing extensive downtime, which is vital in fast-paced industrial environments.

● Importance of Quick Repairs: In industrial settings, downtime can lead to significant losses. Vickers' design enables rapid repairs, ensuring that machinery remains operational.

● Modular Design for Ease of Service: The modular approach means that components can be easily swapped out, further simplifying maintenance tasks. This feature is a testament to Vickers’ commitment to user-friendly designs.

Service Feature | Vickers Vane Pumps |

Maintenance Type | Cartridge design |

Repair Speed | Quick |

Modular Components | Yes |

Vickers Vane Pumps combine low noise, high power density, fluid versatility, and easy serviceability. These features make them an excellent choice for various applications, ensuring reliable performance in demanding environments.

Vickers Vane Pumps are not just about functionality; they also deliver exceptional performance value. This section explores their efficiency, reliability, and adaptability, showcasing why they are a top choice in various industries.

When it comes to efficiency, Vickers Vane Pumps stand out among other pump types. Their design allows for high flow rates while minimizing energy consumption.

● Comparison with Other Pump Types: Compared to gear and piston pumps, Vickers Vane Pumps often provide better efficiency at lower operational costs. This efficiency is crucial for businesses looking to reduce energy expenses and improve overall productivity.

● Importance of High Efficiency in Operational Costs: A pump’s efficiency directly impacts operational costs. By choosing Vickers Vane Pumps, companies can save significantly on energy bills, translating to lower total cost of ownership over time.

Pump Type | Efficiency Rating | Typical Applications |

Vickers Vane Pumps | High | Construction, manufacturing |

Gear Pumps | Moderate | General industrial use |

Piston Pumps | Variable | High-pressure applications |

Reliability is a cornerstone of Vickers Vane Pumps. Built with robust materials, these pumps are designed to withstand harsh operating conditions.

● Robust Construction and Materials: Vickers uses high-quality materials to ensure durability. This construction helps the pumps resist wear and tear, making them ideal for demanding environments.

● Long Service Life and Reduced Downtime: Users can expect a long service life from Vickers Vane Pumps, which reduces the frequency of replacements. This reliability means less downtime, allowing operations to run smoothly.

● Insights into Keister’s Focus on Durability: While Vickers excels in durability, Keister Vane Pumps also emphasize robust construction. However, Vickers' reputation for reliability in various applications often gives it an edge.

Vickers Vane Pumps are incredibly adaptable, making them suitable for a wide range of applications. Their versatility sets them apart in the competitive market.

● Overview of Common Applications: These pumps are commonly used in construction, manufacturing, and agricultural machinery. Their ability to perform under various conditions makes them a go-to choice for many industries.

● Customization Options for Specific Needs: Vickers offers customization options to meet specific customer requirements. This flexibility allows businesses to tailor the pumps to their unique operational needs.

● Highlighting Keister's Ability to Customize: While Vickers provides excellent customization, Keister also offers tailored solutions. However, Vickers’ extensive experience in the industry often results in more refined customization options.

Application | Vickers Vane Pumps | Customization Available |

Construction | Yes | Yes |

Manufacturing | Yes | Yes |

Agriculture | Yes | Limited |

Vickers Vane Pumps deliver impressive performance through their efficiency, reliability, and adaptability. These features make them an excellent investment for businesses seeking dependable hydraulic solutions.

When evaluating hydraulic solutions, the cost and maintenance benefits of Vickers Vane Pumps become clear. These pumps not only offer impressive performance but also provide significant savings over time.

Vickers Vane Pumps are a smart investment for businesses looking to balance initial costs and long-term savings.

● Initial Investment vs. Long-Term Savings: While the upfront cost of Vickers Vane Pumps may be higher than some alternatives, their durability and efficiency lead to substantial savings in the long run. Companies can reduce energy costs and maintenance expenses, making them a cost-effective choice.

● Impact on Operational Efficiency: High efficiency translates to lower operational costs. Vickers Vane Pumps maintain consistent performance, which helps businesses maximize productivity without incurring additional expenses.

● Cost Comparisons with Keister Vane Pumps: When comparing Vickers and Keister Vane Pumps, Vickers often provides better overall value. Although both brands offer quality products, Vickers’ efficiency and durability typically result in lower total costs over time.

Cost Aspect | Vickers Vane Pumps | Keister Vane Pumps |

Initial Investment | Moderate | Lower |

Long-Term Savings | High | Moderate |

Operational Efficiency | High | Moderate |

Maintaining Vickers Vane Pumps is straightforward, thanks to their thoughtful design features.

● Design Features That Simplify Servicing: Vickers pumps incorporate user-friendly designs that make servicing quick and easy. For instance, their cartridge-style components allow for swift replacements, minimizing downtime during maintenance.

● Inventory Support for Quick Replacements: Vickers provides robust inventory support, ensuring that replacement parts are readily available. This accessibility allows businesses to perform repairs quickly, keeping operations running smoothly.

● Emphasizing Vickers' Commitment to Quality Control and Maintenance Support: Vickers is dedicated to quality control, ensuring that every pump meets high standards. Their commitment extends to providing excellent maintenance support, helping customers resolve issues efficiently.

Maintenance Feature | Vickers Vane Pumps |

Servicing Design | Cartridge style |

Replacement Parts Availability | High |

Quality Control Commitment | Strong |

Vickers Vane Pumps not only deliver excellent performance but also offer cost and maintenance advantages. Their design and efficiency translate into significant savings, making them a wise choice for any hydraulic application.

When selecting a hydraulic pump, understanding the various types available is crucial. In this section, we will explore different hydraulic pumps, highlight key differences between Vickers Vane Pumps and their competitors, and discuss the advantages of choosing Vickers.

Hydraulic pumps are essential components in many industrial applications. The most common types include:

● Gear Pumps: These are simple in design and ideal for low-viscosity fluids. They use gears to move fluid and are known for their reliability but can be noisy.

● Piston Pumps: These pumps are highly efficient and can handle high pressures. They are versatile but often more complex and expensive to maintain.

● Vane Pumps: Vickers Vane Pumps fall into this category. They use sliding vanes to create pressure and are known for their smooth operation and efficiency.

Vickers Vane Pumps offer distinctive advantages over gear and piston pumps. Here’s how they compare:

● Efficiency: Vickers Vane Pumps provide higher efficiency at a lower cost of operation compared to gear and piston pumps. This efficiency results in lower energy consumption, making them more economical in the long run.

● Noise Levels: One of the standout features of Vickers Vane Pumps is their low noise operation. In contrast, gear pumps can be quite loud, and piston pumps may produce more vibrations. This makes Vickers an excellent choice for applications where noise reduction is important.

● Maintenance: Vickers pumps are designed for easy maintenance, often featuring cartridge designs that simplify servicing. Gear pumps require more frequent maintenance due to wear on the gears, while piston pumps can be complex and costly to repair.

Feature | Vickers Vane Pumps | Gear Pumps | Piston Pumps |

Efficiency | High | Moderate | High |

Noise Level | Low | High | Moderate |

Maintenance Ease | Easy | Moderate | Complex |

Opting for Vickers Vane Pumps offers several benefits that set them apart from other hydraulic pumps:

● High Efficiency: They maintain high efficiency across various operating conditions, resulting in lower energy costs and improved performance.

● Low Noise Operation: The design of Vickers Vane Pumps ensures minimal noise and vibration, making them suitable for indoor use and sensitive environments.

● Versatile Applications: Vickers pumps are adaptable to a range of applications, from construction to manufacturing, providing flexibility that many competitors cannot match.

In summary, Vickers Vane Pumps excel in efficiency, noise reduction, and ease of maintenance compared to gear and piston pumps. These advantages make them a preferred choice for industries seeking reliable hydraulic solutions.

Vickers Vane Pumps offer exceptional value and numerous benefits. Their high efficiency, low noise levels, and easy maintenance make them ideal for various applications.

These pumps play a crucial role in modern hydraulic systems, ensuring reliable performance and cost savings.

If you're looking for a dependable hydraulic solution, consider Vickers Vane Pumps for your needs.

A: Vickers Vane Pumps are known for their high efficiency, low noise operation, and easy maintenance, making them ideal for various applications.

A: Consider factors like flow rate, pressure requirements, and specific application needs to select the appropriate Vickers Vane Pump.

A: Vickers Vane Pumps typically have a long service life, often exceeding several years with proper maintenance.

A: Regularly check fluid levels, inspect for leaks, and follow the manufacturer's maintenance guidelines for optimal performance.

A: While both brands offer quality pumps, Vickers generally excels in efficiency and durability, leading to lower operational costs.