Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

Are you unsure whether to repair or replace your hydraulic pump? This decision can impact your operations significantly. Hydraulic pumps are vital components in many industries, ensuring machinery runs smoothly.

In this post, we’ll explore the signs that indicate when a hydraulic pump needs attention. You’ll learn about the pros and cons of repairing versus replacing your pump, helping you make an informed choice.

A hydraulic pump is a mechanical device that converts mechanical energy into hydraulic energy. This transformation allows it to generate fluid flow, which powers various machinery and equipment. Hydraulic pumps are essential for applications where high power density and efficiency are required.

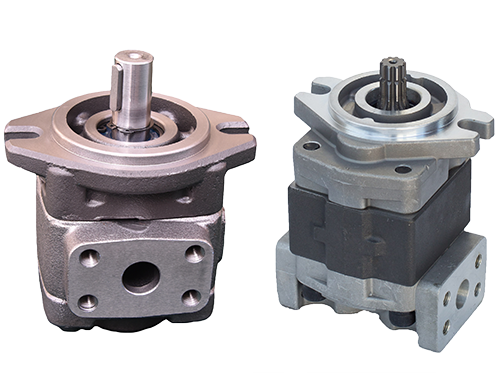

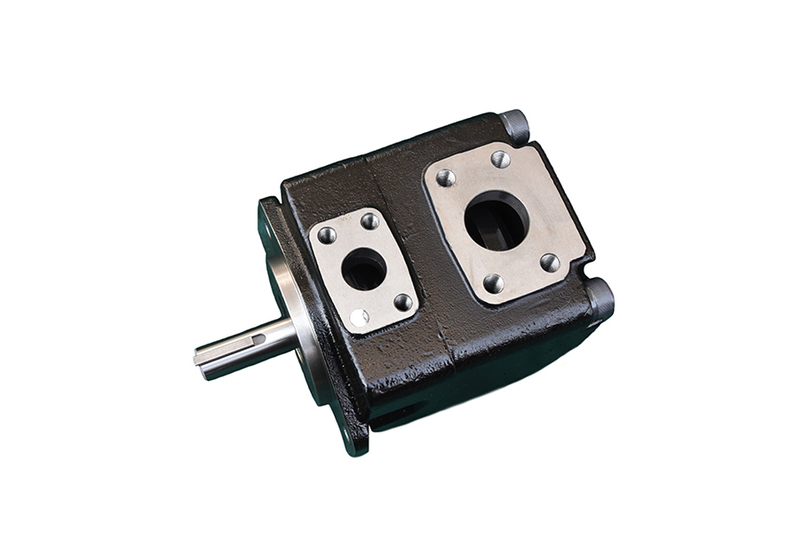

There are two main types of hydraulic pumps: vane pumps and gear pumps.

● Vane Pumps: These pumps use rotating vanes to create a vacuum that draws fluid in. They are known for their ability to maintain a constant flow rate and are often used in applications requiring variable speed.

● Gear Pumps: Gear pumps utilize interlocking gears to move fluid. They are typically more robust and are used in applications where high pressure and flow rates are essential.

Type of Hydraulic Pump | Description | Applications |

Vane Pumps | Uses rotating vanes for flow | Mobile equipment, plastics |

Gear Pumps | Utilizes interlocking gears | Construction, manufacturing |

Hydraulic pumps find their place in numerous industries, playing a crucial role in the operation of various machinery. They are widely used in sectors such as construction, manufacturing, and agriculture.

In the construction industry, hydraulic pumps power equipment like excavators and bulldozers. These machines rely on hydraulic systems to lift heavy loads and perform precise movements. In manufacturing, hydraulic pumps are essential for machines such as injection molders and presses, where they facilitate the movement of materials and components.

Agriculture also benefits from hydraulic pumps. Tractors and harvesters utilize them for tasks like lifting and lowering implements, ensuring efficient operation in the field.

Here are some examples of equipment that utilize hydraulic pumps:

● Excavators: Rely on hydraulic pumps for digging and lifting.

● Forklifts: Use hydraulic systems for lifting loads.

● Tractors: Employ hydraulic pumps for various implements and attachments.

Overall, understanding hydraulic pumps and their applications is vital for optimizing machinery performance and ensuring operational efficiency across different industries.

Zhejiang Keister Hydraulic Co., Ltd., founded in 1958, has established itself as a leader in the hydraulic pump industry. Located in the High-Tech Industrial Park of Taizhou, Zhejiang Province, Keister focuses on the research and development of high-quality hydraulic pumps. Their commitment to innovation ensures that they stay at the forefront of hydraulic technology.

The company’s mission is to enhance the efficiency and durability of machines and equipment worldwide. By investing heavily in R&D and collaborating with top universities, Keister continuously improves its product offerings. This dedication to excellence has earned them recognition as a "High-Tech Enterprise" in Zhejiang Province.

Keister Hydraulic specializes in a diverse range of hydraulic pumps, primarily focusing on hydraulic vane pumps and gear pumps. Their products are designed to meet various industrial needs, ensuring reliability and performance in demanding environments.

Here are some of the main products offered by Keister:

● Hydraulic Vane Pumps: Known for their efficiency and smooth operation, these pumps are ideal for applications requiring consistent flow rates.

● Gear Pumps: Robust and capable of handling high pressures, gear pumps are essential for heavy-duty applications.

Product Type | Key Models | Interchangeability |

Hydraulic Vane Pumps | 35V Series (e.g., 35V35A1A) | Compatible with Vickers and Denison |

Gear Pumps | KHG Series (e.g., KHG H0-20-01) | Fully interchangeable with OEM brands |

Keister's 35V Series includes high-pressure single vane pumps tailored for industrial use, while the KHG Series gear pumps cater to applications in foundry and metal processing industries. Their designs ensure compatibility with leading OEM brands, making them a preferred choice for many operators looking to replace or upgrade their existing hydraulic systems.

By offering a wide range of products and maintaining high standards of quality, Keister Hydraulic plays a significant role in the hydraulic pump market, meeting the diverse needs of various industries.

Recognizing the signs of hydraulic pump failure is essential for maintaining equipment efficiency. Several key symptoms indicate that your hydraulic pump may need immediate attention.

1. Internal and External Leaks: Leaks are one of the most evident signs of pump issues. Internal leaks can reduce system pressure, while external leaks may lead to fluid loss, causing environmental hazards. Regularly check for any signs of leaking fluids around the pump.

2. Fluid Contamination: Contaminated hydraulic fluid can severely impact pump performance. Dirt, debris, or water can enter the system, leading to corrosion and reduced efficiency. It's crucial to monitor fluid quality and replace it when necessary.

3. Loud Noises: Unusual sounds such as grinding, whining, or knocking can indicate mechanical problems within the pump. These noises often suggest wear or damage to internal components, which can escalate if not addressed promptly.

4. Reduced System Performance: If machinery operates slower or less efficiently, it may be a sign of pump failure. A drop in performance can lead to increased energy consumption and operational costs.

Symptoms of Hydraulic Pump Failure | Description |

Internal/External Leaks | Fluid loss affecting pressure and safety |

Fluid Contamination | Dirt and debris causing corrosion |

Loud Noises | Indication of mechanical wear or damage |

Reduced System Performance | Slower operation leading to higher costs |

Early detection of hydraulic pump issues can save significant costs and extend the life of your equipment. By identifying problems before they escalate, you can avoid costly repairs or complete replacements.

Routine maintenance is vital. Regularly inspect your hydraulic systems for leaks, noise, and performance issues. Implementing a scheduled maintenance program can help catch problems early. Here are some tips for effective monitoring:

● Regular Fluid Checks: Monitor fluid levels and quality. Replace fluids according to manufacturer recommendations.

● Visual Inspections: Conduct visual checks for leaks and signs of wear on hoses and fittings.

● Performance Monitoring: Keep track of machinery performance metrics. Sudden changes can indicate pump issues.

By staying proactive and vigilant, you can ensure your hydraulic pump operates smoothly and efficiently, minimizing downtime and maximizing productivity.

Deciding whether to repair or replace your hydraulic pump often comes down to cost. Evaluating repair costs against replacement costs is crucial. If the repair expenses are significantly lower than purchasing a new pump, repairing is usually the better choice.

Typical repair costs can vary based on the type of issue and the parts needed. For instance, minor repairs like replacing seals or O-rings can cost anywhere from $100 to $500. In contrast, major repairs or replacements might range from $1,000 to $5,000 or more, depending on the pump's size and complexity.

Repair Type | Typical Cost Range |

Minor Repairs (seals, O-rings) | $100 - $500 |

Major Repairs (internal components) | $500 - $2,000 |

Full Replacement | $1,000 - $5,000+ |

Certain issues are more suitable for repair than others. Minor wear and tear, such as leaking seals or worn O-rings, can often be fixed quickly and cost-effectively. Addressing these problems promptly can prevent them from escalating into more serious failures.

It's essential to consider the urgency of repairs. If a hydraulic pump is critical to operations, quick turnaround times are vital. Many repair services can expedite minor fixes, allowing you to minimize downtime and keep your machinery running smoothly.

Repairing your hydraulic pump offers several advantages. First, it can significantly extend the life of the pump, allowing you to get more value out of your existing equipment. Regular repairs can help maintain optimal performance and avoid costly breakdowns.

Additionally, repairing rather than replacing has environmental benefits. It reduces waste by keeping old pumps out of landfills and conserves resources by minimizing the need for new manufacturing. By choosing to repair, you contribute to sustainability while also saving money.

In summary, knowing when to repair your hydraulic pump can lead to cost savings, environmental benefits, and extended equipment life. It’s a smart choice for businesses looking to maintain efficiency and manage expenses effectively.

Knowing when to replace your hydraulic pump is crucial for maintaining operational efficiency. Several key indicators can signal that it’s time for a replacement rather than a repair.

1. Structural Integrity Issues: If you notice cracked housings or significant internal damage, it’s often a clear sign that the pump has reached the end of its useful life. Structural failures can lead to catastrophic breakdowns, putting your equipment and safety at risk.

2. High Repair Costs Compared to Replacement Costs: When repair costs exceed 50% of the price of a new pump, replacement becomes a more cost-effective option. This ratio helps you evaluate whether investing in repairs is worth it or if you should opt for a new unit.

3. Obsolescence of Parts and Models: If the pump model is outdated and parts are hard to find, replacement might be necessary. Obsolete models can lead to longer downtimes while searching for parts, and they may not perform as efficiently as newer models.

Indicator | Replacement Consideration |

Structural Integrity Issues | Cracks or major damage indicate replacement |

High Repair Costs | Repairs over 50% of new pump cost suggest replacement |

Obsolescence of Parts/Models | Difficulty in sourcing parts signals need for a new pump |

When making the decision to replace your hydraulic pump, consider the long-term implications. Reliability is paramount, especially in critical systems where downtime can lead to significant losses. A new pump typically offers improved performance, efficiency, and reliability, ensuring smoother operations.

Additionally, many new pumps come with warranties that provide peace of mind. These warranties can cover parts and labor for a specified period, reducing future maintenance costs. Investing in a new hydraulic pump not only enhances performance but also safeguards against unexpected failures.

In summary, identifying the right time to replace your hydraulic pump involves assessing structural integrity, repair costs, and the availability of parts. Long-term reliability and warranty benefits further support the case for replacement, helping you make informed decisions for your operations.

Rebuilding or remanufacturing a hydraulic pump offers a viable alternative to both repair and replacement. This process involves disassembling the pump, inspecting each component, and replacing worn parts with new or refurbished ones. After thorough cleaning and reassembly, the pump is tested to ensure it meets performance standards.

The costs associated with rebuilding can be significantly lower than purchasing a new unit. Typically, rebuilding a hydraulic pump may range from 40% to 70% of the cost of a new pump, depending on the extent of wear and required parts. This makes it an attractive option for businesses looking to save money while extending the life of their equipment.

Cost Comparison | Rebuilding Cost | New Pump Cost |

Typical Range | 40% - 70% of new price | Full retail price |

One of the key advantages of remanufactured hydraulic pumps is the assurance of quality and performance. Rebuilding processes often adhere to strict industry standards, ensuring that the remanufactured units operate effectively and reliably. Many manufacturers provide warranties on these units, which can range from six months to two years, depending on the company and the specific pump.

These warranties not only cover defects in materials and workmanship but also reflect the confidence that manufacturers have in their remanufactured products. This added assurance can give businesses peace of mind, knowing they are investing in a reliable solution without the hefty price tag of a brand-new pump.

Warranty Offerings | Typical Duration | Coverage |

Standard Warranty | 6 months - 2 years | Defects in materials |

Extended Warranty Options | Available for purchase | Additional coverage |

In summary, rebuilding or remanufacturing offers a middle ground for those facing hydraulic pump issues. It combines cost savings with the assurance of quality, making it a practical choice for many businesses.

When faced with the dilemma of whether to repair or replace your hydraulic pump, having a clear decision matrix can help streamline the process. Below is a cost comparison table that outlines typical expenses associated with both options, alongside common damage scenarios and recommended actions.

Decision Factor | Repair Cost Range | Replacement Cost Range | Recommended Action |

Minor leaks | $100 - $300 | $1,000 - $3,000 | Repair |

Significant internal damage | $500 - $1,500 | $2,000 - $5,000 | Replace if repairs exceed 50% of new cost |

Obsolete model | $200 - $500 | $1,500 - $4,000 | Replace if parts are hard to find |

Routine maintenance issues | $50 - $150 | N/A | Repair |

In this table, you can see how the costs vary based on the type of damage. For minor repairs, fixing the pump is usually the best option. However, if you encounter significant internal damage or if the pump is obsolete, replacement may be more cost-effective.

Assessing the severity of pump issues is critical in making the right decision. Start by evaluating the symptoms: Are there unusual noises? Is there a significant drop in performance? These signs can help gauge the urgency of the situation.

When considering your operational needs, think about factors such as:

● Downtime: How quickly do you need the pump back in operation? If downtime is critical, a replacement may be faster than waiting for repairs.

● Future Reliability: Is the pump essential for ongoing operations? Investing in a new pump might provide better long-term reliability.

● Budget Constraints: What is your budget for repairs or replacement? If funds are limited, a repair might be the only feasible option.

By weighing these factors, you can make an informed decision that aligns with your operational goals and financial constraints. Whether you choose to repair or replace, understanding the nuances of each option will help ensure that your hydraulic systems continue to function efficiently.

In this article, we explored the critical decision of whether to repair or replace your hydraulic pump. Key points included assessing costs, identifying damage, and considering long-term reliability.

Ultimately, making informed decisions is vital for efficient operations. It's essential to evaluate your specific situation carefully.

We encourage consulting professionals for expert assessment and tailored advice. This will help ensure the best outcome for your hydraulic systems.