Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

Hydraulic systems power much of today’s mobile equipment—from construction machinery to agricultural tractors and material-handling vehicles. At the heart of many of these systems is the extenal gear pump, a compact, cost-effective, and dependable technology that has been trusted for decades. Despite the rise of more complex hydraulic pump types, external gear pumps remain a staple in mobile applications because of their simplicity, durability, and excellent performance under tough conditions.

This article explores what makes external gear pumps unique, their advantages, the critical role they play in mobile hydraulic systems, and why they continue to be a preferred choice in industries where efficiency and reliability matter most.

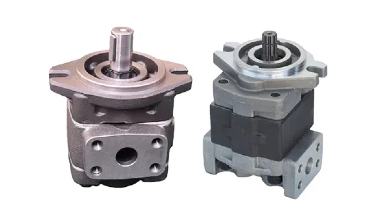

An extenal gear pump is a positive displacement pump that uses two meshing gears to move fluid. The pump consists of:

Two gears (driving gear and driven gear) that rotate in opposite directions.

A pump housing that encases the gears and provides sealing surfaces.

Inlet and outlet ports through which hydraulic fluid enters and exits.

As the gears rotate, fluid is trapped between the gear teeth and the housing, then carried around the outside of the gears to the outlet side. This mechanism creates a consistent flow of fluid with each rotation, making external gear pumps highly reliable for continuous operation.

The enduring popularity of extenal gear pumps in mobile hydraulic systems can be attributed to several distinct advantages:

Extenal gear pumps are relatively small compared to other types of hydraulic pumps, making them easy to integrate into mobile equipment where space is limited.

With few moving parts and a straightforward design, these pumps are less prone to failure. Their rugged construction ensures dependable performance even under heavy-duty conditions.

Extenal gear pumps are generally more affordable than vane or piston pumps, offering excellent value for applications that do not require extreme pressures or variable displacement.

They deliver a steady, pulse-free flow of hydraulic fluid, which is crucial for smooth machine operation and precise control of actuators.

Extenal gear pumps can handle a variety of fluids, including standard hydraulic oils, lubricants, and some synthetic fluids, adding to their versatility.

Hydraulic systems are the backbone of mobile equipment. Whether lifting, digging, steering, or braking, hydraulic power enables compact machines to deliver enormous force with precision. External gear pumps are central to these systems in several ways:

In construction equipment such as excavators, skid steers, and loaders, extenal gear pumps supply the pressurized fluid required to move cylinders and motors. Their steady flow ensures efficient lifting, pushing, and digging.

Mobile equipment like tractors and forklifts often use hydraulic power steering. Extenal gear pumps provide the necessary fluid pressure for smooth and responsive steering, even in tight working environments.

Beyond primary movement, extenal gear pumps power auxiliary systems such as cooling fans, winches, and attachments. Their ability to operate reliably under variable loads makes them ideal for multitasking machinery.

In some heavy-duty vehicles, hydraulic braking systems rely on gear pumps for consistent fluid pressure. Safety and reliability are enhanced by the pump’s steady performance.

When evaluating extenal gear pumps for mobile hydraulic applications, several performance factors stand out:

While not as high as piston pumps, extenal gear pumps typically handle pressures up to 250 bar (3,600 psi), sufficient for most mobile equipment needs.

Depending on size and design, they can provide a wide range of flow rates, making them suitable for both compact and large machines.

Modern designs incorporate advanced materials and tighter tolerances, improving volumetric efficiency while reducing energy loss.

Noise can be a concern in mobile equipment. Many extenal gear pumps now include helical gears or special profiles to minimize vibration and noise, improving operator comfort.

Why choose extenal gear pumps over alternatives?

Compared to vane pumps: Gear pumps are more rugged and can handle dirtier fluids, while vane pumps are quieter but less durable in harsh environments.

Compared to piston pumps: Piston pumps offer higher efficiency and pressure but are more complex and costly. Gear pumps provide a simpler and more economical solution for moderate pressure needs.

This balance of performance, simplicity, and cost makes extenal gear pumps a sweet spot for mobile hydraulic systems.

Extenal gear pumps can be found across a wide range of mobile equipment sectors:

Bulldozers, backhoes, skid steers, and excavators depend on gear pumps for lift arms, booms, and steering. Their ruggedness ensures minimal downtime in demanding environments.

Tractors, harvesters, and sprayers use hydraulic systems powered by extenal gear pumps. From lifting implements to steering and powering attachments, reliability is critical during planting and harvest seasons.

Forklifts and telehandlers rely on hydraulic power for lifting heavy loads. Extenal gear pumps provide the consistent performance needed for safe and efficient operation.

Harsh operating environments demand robust equipment. Gear pumps perform reliably under dust, debris, and temperature extremes.

Garbage trucks, snowplows, and fire engines all use hydraulic systems powered by extenal gear pumps for tasks like compaction, lifting, or spraying.

While extenal gear pumps are known for their reliability, proper maintenance ensures optimal performance and extends service life:

Regular Oil Checks: Use clean, high-quality hydraulic oil to reduce wear.

Filter Replacement: Dirty oil is the enemy of hydraulic systems—filters must be maintained regularly.

Seal Inspection: Worn seals can cause leakage and reduced efficiency.

Proper Sizing: Ensuring the pump is correctly matched to system requirements prevents premature wear.

With proper care, extenal gear pumps can last thousands of operating hours, minimizing downtime and replacement costs.

As mobile equipment evolves toward higher efficiency and sustainability, extenal gear pumps are also advancing:

Improved Materials: Advanced alloys and coatings increase wear resistance.

Noise-Reduction Technologies: Helical gears and precision machining reduce vibration.

Integration with Electronics: Smart sensors and controls are being added to monitor pump performance in real time, supporting predictive maintenance.

Eco-Friendly Fluids: Compatibility with biodegradable and synthetic fluids supports sustainability initiatives.

These innovations ensure that extenal gear pumps will continue to play a central role in mobile hydraulics for years to come.

In the world of mobile hydraulic equipment, extenal gear pumps strike an ideal balance between simplicity, reliability, and performance. Their compact design, cost-effectiveness, and ability to handle a wide range of operating conditions make them indispensable in construction, agriculture, material handling, and beyond.

For businesses and operators seeking dependable hydraulic solutions, working with experienced manufacturers is essential. Companies like Zhejiang Keister Hydraulic Co., Ltd. specialize in producing high-quality external gear pumps designed for mobile equipment applications. Their expertise and commitment to innovation make them a trusted partner for industries worldwide.

If you are looking to boost the reliability and efficiency of your hydraulic systems, consider exploring the solutions offered by Zhejiang Keister Hydraulic Co., Ltd.—a company dedicated to powering the future of mobile hydraulics.