Views: 0 Author: Site Editor Publish Time: 2025-10-08 Origin: Site

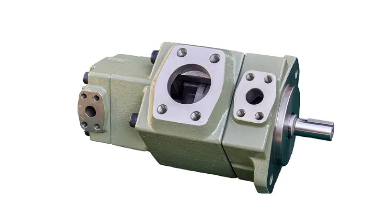

Vane pumps are widely used in hydraulic systems across industries ranging from manufacturing and construction to automotive and marine applications. Known for their compact design, smooth operation, and consistent flow, vane pumps are a popular choice for medium-pressure systems. Despite their reliability, like all hydraulic components, they are not immune to problems. Understanding the common issues that can occur with vane pumps and how to troubleshoot them is crucial for maintaining system performance and preventing costly downtime.

Before diving into common problems, it’s helpful to understand the basic operation of a vane pump. Vane pumps are positive displacement pumps, meaning they deliver a fixed volume of fluid per rotation.

Key components include:

Rotor – rotates inside the pump casing.

Vaness – sliding blades that extend and retract from the rotor, creating chambers for fluid to move.

Pump casing – houses the rotor and vanes, maintaining precise clearances.

Inlet and outlet ports – allow hydraulic fluid to enter and exit the pump.

As the rotor spins, the vanes trap fluid and push it from the inlet to the outlet, producing a smooth, continuous flow. Maintaining the clearances between vanes, rotor, and casing is essential for proper operation; any wear, contamination, or misalignment can lead to problems.

One of the most frequent issues reported with vane pumps is a drop in flow rate. This can manifest as slower actuator movement, reduced pressure, or inconsistent system performance.

Causes:

Worn vanes or rotor – Over time, vanes can wear down, reducing their ability to trap fluid.

Casing wear – Grooves or scoring inside the pump housing can lead to internal leakage.

Air entrainment – Air entering the hydraulic fluid can create bubbles, reducing volumetric efficiency.

Contaminated fluid – Dirt, debris, or varnish buildup can interfere with vane movement.

Troubleshooting Tips:

Inspect vanes and rotor for wear or damage; replace if necessary.

Check pump casing for scratches or grooves; resurfacing may be required.

Ensure the hydraulic reservoir is properly vented to prevent air suction.

Flush the system and replace contaminated fluid, using a quality filter.

Vane pumps are generally smooth-running, so unusual noise or vibration often indicates a problem that requires attention.

Causes:

Cavitation – Occurs when the pump draws in insufficient fluid, creating vapor pockets that collapse and cause noise.

Worn or uneven vanes – Can lead to imbalance and vibration.

Loose mounting – Misaligned or loose pumps can vibrate excessively during operation.

Troubleshooting Tips:

Verify inlet line sizing and fluid level to prevent cavitation.

Inspect vanes for uneven wear and replace as needed.

Check all mounting bolts and alignment; tighten or adjust as necessary.

Consider adding a suction strainer to prevent debris from entering the pump.

Excessive heat in a vane pump can damage internal components, degrade hydraulic fluid, and reduce system efficiency.

Causes:

High system pressure – Operating above the pump’s rated pressure can generate excessive heat.

Low fluid level or poor circulation – Reduces cooling and lubrication of moving parts.

Contaminated or degraded hydraulic fluid – Loses its ability to lubricate and dissipate heat.

Troubleshooting Tips:

Ensure the system is operating within the manufacturer’s recommended pressure range.

Maintain proper fluid level and verify the reservoir capacity is adequate.

Replace degraded fluid and check for any restrictions in the cooling or filtration system.

Consider installing an external cooler if operating in high-temperature environments.

Internal or external leakage can significantly reduce pump efficiency and create safety hazards.

Causes:

Worn vanes, rotor, or casing – Leads to internal leakage and reduced output.

Faulty seals – O-rings or gaskets can degrade over time, causing external leaks.

Improper installation – Misalignment or uneven mounting can cause leakage points.

Troubleshooting Tips:

Inspect and replace worn vanes, rotor, or casing components.

Check all seals and gaskets; replace if cracked or hardened.

Ensure proper alignment during installation and tighten mounting bolts to specification.

Monitor system pressure and temperature to prevent premature seal failure.

Cavitation, caused by vapor bubbles collapsing inside the pump, can erode metal surfaces and lead to early pump failure.

Causes:

Low inlet pressure – Often due to a restricted suction line, clogged filter, or insufficient fluid level.

Excessive pump speed – Pumping too fast can cause vapor formation in low-pressure areas.

Troubleshooting Tips:

Check inlet lines for blockages and ensure suction filters are clean.

Verify the pump speed matches the manufacturer’s recommendations.

Ensure fluid viscosity is within the recommended range for operating temperature.

A vane pump may fail to achieve required system pressure, affecting overall hydraulic performance.

Causes:

Worn internal components – Vanes, rotor, or casing clearances increasing over time.

Relief valve issues – Malfunctioning valves can bleed off pressure.

Contamination – Dirt or debris affecting pump efficiency.

Troubleshooting Tips:

Inspect pump internals for wear and replace components if necessary.

Test relief valves for correct operation and adjust or replace as needed.

Flush the system and use clean hydraulic fluid to prevent contamination.

Regular preventive maintenance is essential for ensuring the reliability, efficiency, and longevity of vane pumps. By addressing minor issues before they escalate, operators can reduce unplanned downtime, avoid costly repairs, and maintain consistent hydraulic system performance. Here are several key preventive measures in detail:

Maintaining proper fluid levels is critical for pump performance. Low hydraulic fluid can cause cavitation, overheating, and inadequate lubrication, leading to premature wear. Additionally, the quality of the hydraulic fluid directly affects the longevity of internal components:

Always follow the manufacturer’s recommended fluid type and replacement schedule.

Regularly check for discoloration, cloudiness, or unusual odors, which may indicate contamination or degradation.

Replace fluid promptly if it exceeds the recommended service life to maintain optimal viscosity and lubrication properties.

Filters protect the pump from dirt, debris, and other contaminants that can damage vanes, rotors, and casing surfaces. Neglecting filter maintenance can lead to accelerated wear and system inefficiency. Best practices include:

Replace or clean filters according to the manufacturer’s guidelines.

Inspect filter elements for signs of clogging or contamination between scheduled maintenance.

Consider using high-efficiency filters if the system operates in particularly dirty or harsh environments.

The vanes, rotor, and casing are the heart of the pump. Over time, wear or minor damage can reduce efficiency and cause performance issues:

Schedule periodic inspections to detect early signs of wear, scoring, or pitting.

Look for uneven vane wear, which may indicate misalignment or lubrication problems.

Replace worn or damaged components before they affect overall pump performance.

Proper mounting and alignment are often overlooked but are critical for reducing vibration, noise, and mechanical stress:

Ensure all mounting bolts are tightened to the manufacturer’s specifications.

Verify the pump is aligned correctly with the drive motor or hydraulic system to prevent uneven loads.

Realign the pump promptly if misalignment is detected to avoid premature wear of bearings and gears.

Vane pumps are reliable and efficient components in hydraulic systems, but they are not immune to issues such as reduced flow, noise, overheating, leakage, cavitation, and pressure loss. Understanding these common problems and knowing how to troubleshoot them is essential for maintaining optimal system performance.

Preventive maintenance, including regular fluid checks, filtration, and inspections, is critical to avoiding costly repairs and extending the life of the pump. For manufacturers and operators seeking high-quality vane pumps or expert guidance in troubleshooting and maintenance, Zhejiang Keister Hydraulic Co., Ltd. provides reliable solutions and technical support. Their team can help ensure your hydraulic systems operate efficiently and dependably. To learn more, visit Zhejiang Keister Hydraulic Co., Ltd. or contact their experts directly.