Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

Are you wondering if external gear pumps can self-prime? Understanding their capabilities is crucial for effective hydraulic system performance. In this article, we’ll clarify whether external gear pumps possess self-priming features. You’ll learn about their operation, advantages, and what to consider when using them in various applications.

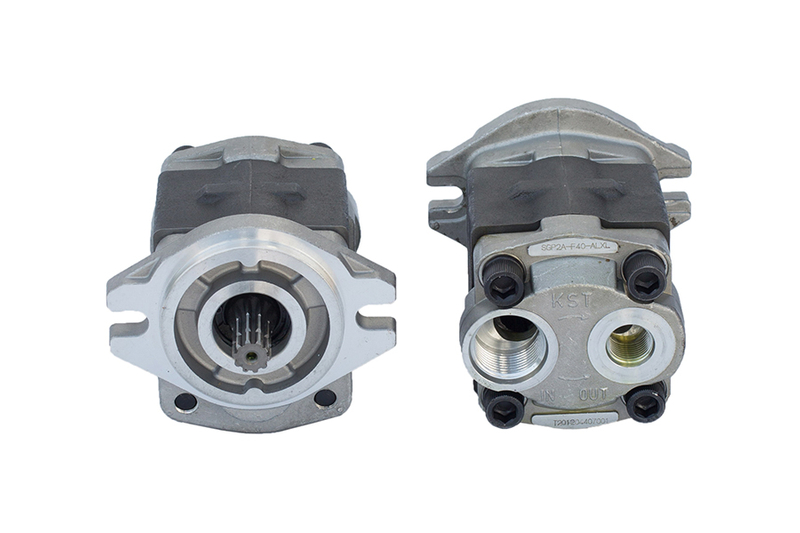

External gear pumps are widely used devices in various industrial applications. They consist of two gears that mesh together, creating a sealed chamber that moves fluid as the gears rotate. This design makes them highly efficient for transferring liquids.

External gear pumps are positive displacement pumps. They work by trapping a fixed volume of fluid between the gear teeth and the pump casing. As the gears turn, this trapped fluid is pushed from the inlet to the outlet, ensuring a consistent flow rate.

The operation of external gear pumps is straightforward. When the gears rotate, they create a vacuum at the inlet, allowing fluid to enter the pump. This process continues as the gears mesh, forcing the fluid out through the discharge port.

Here’s a simple illustration of the operating principle:

Step | Description |

1 | Gears rotate, creating a vacuum. |

2 | Fluid enters the pump through the inlet. |

3 | Gears mesh, pushing fluid out through the outlet. |

External gear pumps have several notable features:

● High Efficiency: They provide a consistent flow rate, making them ideal for various applications.

● Durability: Built with robust materials, they withstand high pressures and harsh conditions.

● Versatility: Suitable for a wide range of fluids, including oils and chemicals.

These features make them a popular choice in industries like automotive, manufacturing, and hydraulic systems.

External gear pumps are used in numerous applications, including:

● Hydraulic Systems: They provide hydraulic power for machinery and equipment.

● Oil Transfer: Commonly used in lubrication systems and fuel injection.

● Chemical Processing: Effective for moving various chemicals and solvents.

One leading manufacturer of external gear pumps is Zhejiang Keister Hydraulic Co., Ltd. Their commitment to innovation and quality ensures that customers receive reliable hydraulic solutions tailored to their needs. Keister's pumps are designed for optimal performance, making them a trusted choice in the industry.

In summary, external gear pumps are essential tools in many sectors, known for their efficiency and reliability. Understanding their definition, operating principles, features, and applications is crucial for anyone working with hydraulic systems.

Self-priming refers to a pump's ability to draw fluid into its system without needing manual priming. This feature is crucial for many applications, as it simplifies operation and enhances efficiency. In the context of external gear pumps, understanding self-priming is essential for optimal performance.

A self-priming pump can evacuate air from its suction line and create a vacuum, allowing it to draw in liquid. This process means the pump can start operating even when the suction line isn't fully filled. For many users, this capability saves time and reduces the need for additional equipment.

Self-priming pumps offer several advantages in various industries:

● Convenience: They eliminate the need for manual priming, making them easier to operate.

● Reduced Downtime: Quick start-up times mean less waiting before the pump can begin its work.

● Versatility: They can handle situations where the pump is positioned above the liquid level, such as in certain hydraulic systems.

Here’s a quick overview of why self-priming is important:

Benefit | Description |

Convenience | No manual priming needed, simplifying operation. |

Reduced Downtime | Faster start-up leads to increased productivity. |

Versatility | Works well in various configurations and settings. |

Self-priming pumps operate based on a simple principle: they create a vacuum that allows atmospheric pressure to push liquid into the pump. Here's a breakdown of the process:

1. Vacuum Creation: As the pump starts, the rotating components generate a vacuum in the suction line.

2. Air Evacuation: The vacuum pulls air out of the suction line, reducing pressure.

3. Liquid Intake: Atmospheric pressure pushes the liquid up into the pump, filling the chamber.

This mechanism is common in various positive displacement pumps, including external gear pumps. However, it's important to note that not all external gear pumps are designed to be self-priming.

In the case of Zhejiang Keister Hydraulic Co., Ltd., their external gear pumps are engineered with precision to enhance performance, but users must confirm specific models' capabilities regarding self-priming. Understanding these features helps in selecting the right pump for your needs, ensuring efficient and reliable operation.

When discussing external gear pumps, a common question arises: are they self-priming? Understanding their self-priming capabilities is crucial for anyone considering these pumps for their applications. Generally speaking, external gear pumps are not classified as self-priming. This distinction is important when selecting the right pump for specific needs.

External gear pumps are designed to move fluids efficiently through a system. However, they typically require the suction line to be filled with liquid before operation. Unlike self-priming pumps, which can draw in liquid from a low level, external gear pumps depend on an already primed system.

Here’s a quick look at their capabilities:

Capability | Description |

Self-Priming | Generally not self-priming. |

Initial Priming Requirement | Must have liquid in the suction line. |

Efficiency | High efficiency once primed. |

The primary reason external gear pumps are not considered self-priming lies in their design. These pumps rely on positive displacement, meaning they need a full suction line to function properly. If air enters the system, it can lead to cavitation, which reduces efficiency and can damage the pump.

In contrast, self-priming pumps have mechanisms that allow them to evacuate air and draw in liquid. This difference is critical when assessing the suitability of external gear pumps for various applications.

Understanding how external gear pumps compare to other pump types, such as centrifugal pumps, provides valuable insight. Here’s a brief comparison:

Feature | External Gear Pumps | Centrifugal Pumps |

Self-Priming Capability | Not self-priming | Often self-priming |

Fluid Handling | Handles viscous fluids well | Best for low-viscosity fluids |

Efficiency | High efficiency at constant flow rates | Efficiency varies with flow conditions |

Centrifugal pumps are often preferred for applications requiring self-priming capabilities. They can handle varying fluid levels and are easier to operate in situations where the pump is positioned above the liquid source.

In summary, while external gear pumps excel in various applications, their lack of self-priming ability means users must ensure proper priming before operation. This knowledge is essential for making informed decisions about pump selection, especially when considering the offerings from Zhejiang Keister Hydraulic Co., Ltd. Their expertise in hydraulic solutions includes a range of pumps tailored for specific operational needs, ensuring reliable performance in various settings.

Understanding the priming process in external gear pumps is essential for ensuring they operate efficiently. Unlike self-priming pumps, external gear pumps require specific conditions to initiate fluid flow. Let's dive into how this process works and what you need to do to properly prime these pumps.

The priming process begins when the pump is activated. For external gear pumps, it’s crucial that the suction line is filled with liquid before starting. This is because the pump relies on a continuous flow of fluid to create pressure. If the suction line contains air, the pump will not function correctly, leading to potential damage.

1. Initial Setup: Ensure the pump and suction line are properly connected and sealed.

2. Filling the Suction Line: Manually fill the suction line with liquid to eliminate any air pockets.

3. Starting the Pump: Activate the pump, allowing it to draw fluid into the chamber.

4. Monitoring: Watch for any signs of cavitation or air leaks as the pump operates.

Having a filled suction line is critical for the operation of external gear pumps. When the pump starts, it creates a vacuum that pulls fluid into the chamber. If air is present, the pump cannot generate the necessary pressure to move the liquid. This requirement differentiates external gear pumps from other types, such as centrifugal pumps, which can handle air better.

Positive pressure at the pump inlet is vital for maintaining fluid flow. It ensures that the pump can continuously draw fluid without interruption. In external gear pumps, this pressure is generated as the gears rotate, creating a sealed chamber that forces the fluid through the system. If the pressure drops due to air in the line, the pump may stall or fail to operate efficiently.

Manually priming an external gear pump involves a few straightforward steps:

● Step 1: Disconnect the pump from the power source for safety.

● Step 2: Open the vent valve to allow air to escape.

● Step 3: Fill the suction line and pump housing with the appropriate fluid.

● Step 4: Close the vent valve and reconnect the power.

● Step 5: Start the pump and monitor for proper operation.

Zhejiang Keister Hydraulic Co., Ltd. designs external gear pumps with features that enhance priming efficiency. Their pumps often include:

● Integrated Check Valves: These prevent backflow and help maintain positive pressure.

● Optimized Inlet Designs: These reduce the likelihood of air entrapment, ensuring smoother operation.

● Durable Materials: These withstand high pressures and temperatures, extending the pump's lifespan.

By understanding the priming process and the specific requirements of external gear pumps, users can ensure optimal performance. This knowledge is essential for anyone looking to utilize these pumps effectively in their applications.

While external gear pumps are not self-priming, they offer several advantages that make them a preferred choice in many industrial applications. Their design and functionality provide unique benefits that enhance performance and reliability.

One of the significant advantages of non-self-priming external gear pumps is their simpler design. Without the need for complex self-priming mechanisms, these pumps can operate more efficiently. This simplicity leads to:

● Lower Maintenance Requirements: Fewer moving parts mean less wear and tear, reducing the need for frequent repairs.

● Consistent Performance: They maintain a steady flow rate, making them ideal for applications requiring precise fluid transfer.

Here’s a quick overview of efficiency benefits:

Benefit | Description |

Lower Maintenance | Simpler design leads to fewer repairs. |

Consistent Performance | Maintains steady flow rates. |

Cavitation can be a significant issue in pumping systems, leading to damage and inefficiency. Non-self-priming external gear pumps are less prone to cavitation due to their operational characteristics. Since they require a filled suction line, there’s a lower likelihood of air entering the system. This design feature results in:

● Increased Reliability: A reduced risk of cavitation means fewer operational failures.

● Longer Lifespan: With less stress on the pump components, these pumps tend to last longer, providing better value over time.

External gear pumps are known for their excellent flow control capabilities. Their design allows for precise adjustments to flow rates, making them suitable for various applications, from hydraulic systems to chemical processing. Some key features include:

● Adjustable Speed Options: Users can modify the pump speed to match the application's requirements.

● Accurate Displacement: The positive displacement mechanism ensures that the volume of fluid moved is consistent, enhancing process control.

Zhejiang Keister Hydraulic Co., Ltd. exemplifies quality and innovation in the design of external gear pumps. Their commitment to excellence is reflected in their manufacturing processes and product features. Keister’s pumps are engineered to maximize efficiency while minimizing the risk of cavitation. Additionally, their focus on precise flow control ensures that customers receive reliable and effective pumping solutions tailored to their specific needs.

By choosing non-self-priming external gear pumps, industries can benefit from improved efficiency, reduced cavitation risks, and precise flow control, all while relying on the trusted quality of manufacturers like Keister.

A: Not all external gear pumps are non-self-priming; some models may have features that allow for limited self-priming capabilities.

A: External gear pumps typically cannot lift fluid when self-priming; they require a filled suction line to operate effectively.

A: Poor installation can lead to air leaks, reduced efficiency, and potential cavitation, ultimately affecting the pump's performance.

A: External gear pumps are generally less versatile than dedicated self-priming pumps, which can handle varying fluid levels without manual priming.

A: Yes, ensuring proper sealing and minimizing air pockets can enhance the priming capabilities of external gear pumps post-installation.

In summary, external gear pumps are generally not self-priming. They require a filled suction line to function properly. These pumps offer several advantages, including efficiency and precise flow control. When selecting an external gear pump, consider reliability and quality, especially from manufacturers like Keister. Their expertise in hydraulic solutions ensures optimal performance. For specific applications and needs, consulting with experts is highly recommended. This will help you make the best choice for your pumping requirements.